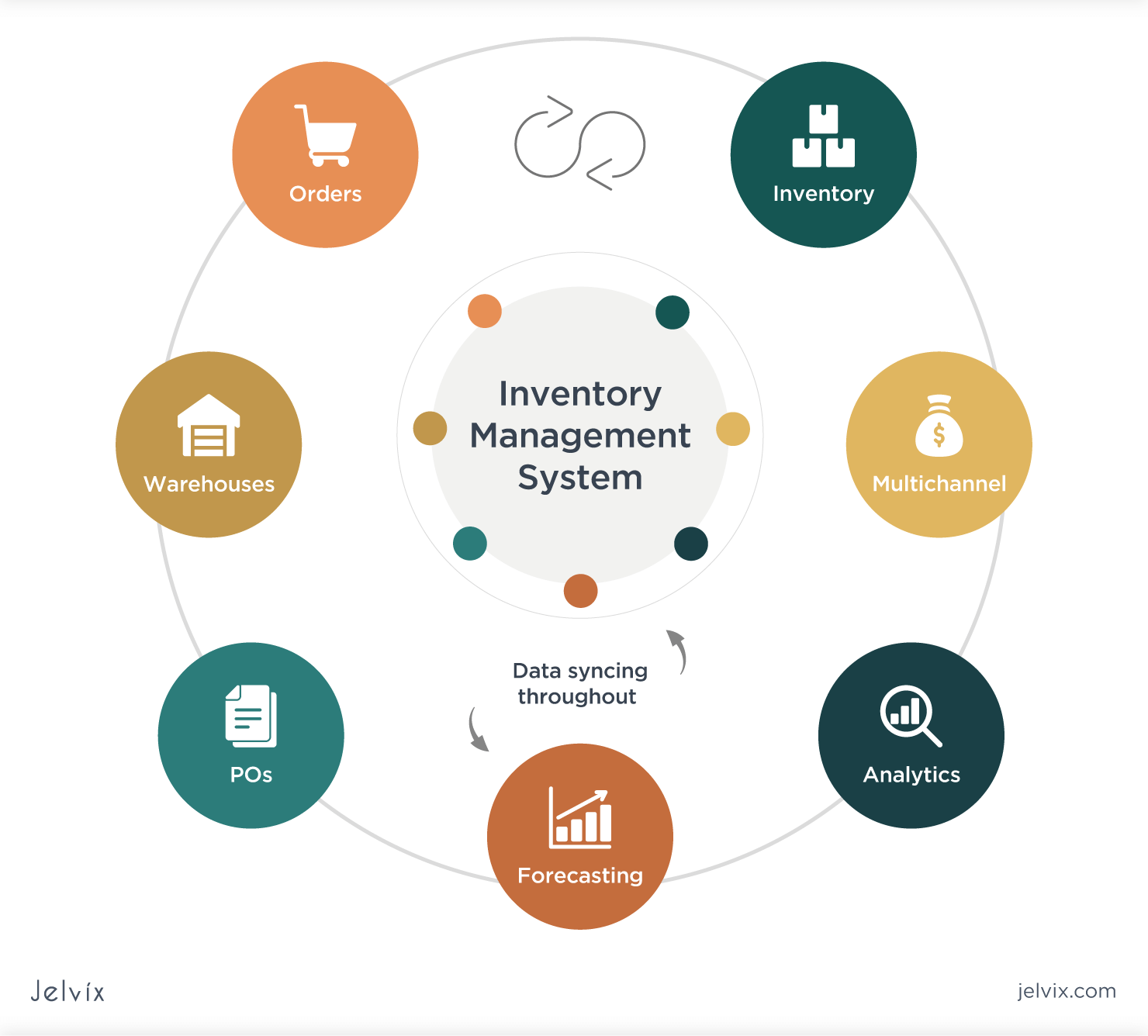

Business inventory systems are the backbone of efficient inventory management, providing businesses with real-time visibility into their stock levels, enabling them to optimize inventory levels, reduce costs, and improve customer service.

Inventory management is a critical aspect of any business, regardless of size or industry. An effective inventory system provides businesses with the data they need to make informed decisions about their inventory, including how much to order, when to order, and where to store it.

Overview of Business Inventory Systems

Business inventory systems are crucial tools that enable organizations to track and manage their inventory effectively. These systems provide real-time visibility into inventory levels, helping businesses optimize their supply chain, reduce costs, and enhance customer satisfaction.

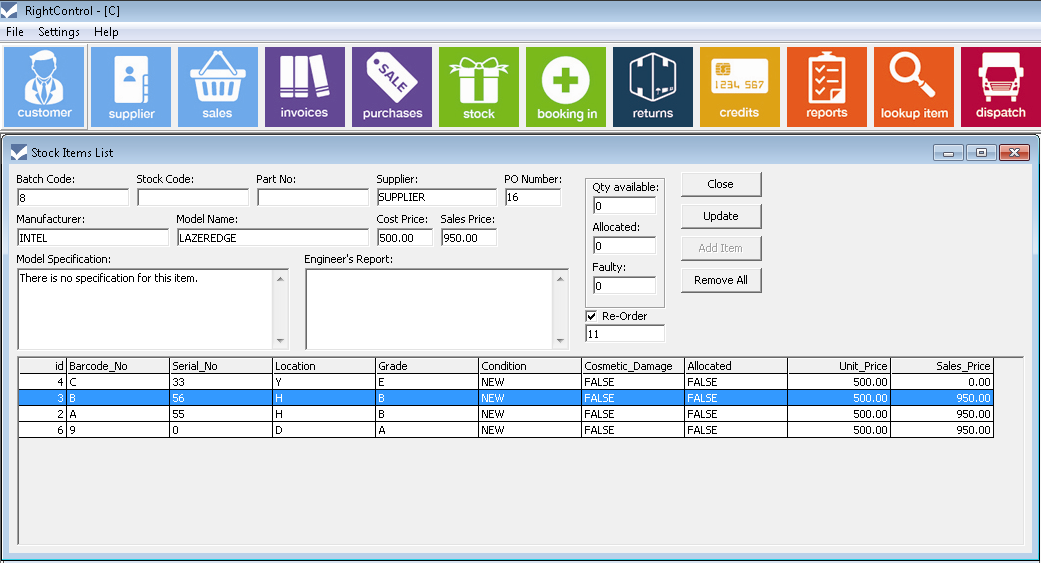

There are various types of inventory systems used across industries, each tailored to specific business needs. Some common examples include:

- Periodic Inventory System: A simple system where inventory is counted and recorded at regular intervals, such as monthly or quarterly.

- Perpetual Inventory System: A more advanced system that continuously tracks inventory levels as transactions occur, providing real-time data.

- Just-in-Time (JIT) Inventory System: A lean approach that aims to minimize inventory levels by receiving goods only when they in Inventory Management

- Enhanced Demand Forecasting: AI and ML algorithms can analyze historical data and external factors to predict future demand more accurately, reducing the risk of stockouts and overstocking.

- Optimized Inventory Levels: These technologies can determine optimal inventory levels based on demand forecasts, lead times, and safety stock requirements, ensuring that businesses have the right amount of inventory on hand.

- Improved Customer Service: Reduced stockouts and overstocking lead to improved customer satisfaction, as customers are more likely to receive the products they need, when they need them.

- Reduced Inventory Costs: AI and ML algorithms can help businesses identify and eliminate excess inventory, reducing storage costs and the risk of obsolescence.

Challenges of Adopting AI and ML in Inventory Management

- Data Quality and Availability: AI and ML algorithms require large amounts of high-quality data to generate accurate predictions. Businesses need to ensure they have access to reliable and up-to-date data.

- Implementation Costs: Implementing AI and ML solutions can be expensive, especially for small businesses with limited resources.

- Technical Expertise: AI and ML algorithms are complex and require specialized technical expertise to implement and maintain.

- Resistance to Change: Some businesses may be hesitant to adopt new technologies, especially if they are unfamiliar with AI and ML.

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to maintain optimal stock levels, reduce costs, and enhance customer satisfaction. Here are some best practices to consider:

Regular Inventory Audits and Cycle Counting

Regular inventory audits involve physically counting and verifying the accuracy of inventory records. Cycle counting, on the other hand, involves counting a portion of inventory on a regular basis, rather than all at once. These practices help identify discrepancies, prevent shrinkage, and ensure inventory accuracy.

Reducing Inventory Waste and Obsolescence

Implementing strategies to reduce inventory waste and obsolescence is essential. This includes:

– First-in, First-out (FIFO): Selling older inventory before newer inventory, reducing the risk of obsolescence.

– Just-in-Time (JIT): Ordering inventory only when needed, minimizing storage costs and reducing the likelihood of obsolescence.

– Vendor Managed Inventory (VMI): Allowing suppliers to manage inventory levels, reducing overstocking and obsolescence.

– Safety Stock Optimization: Determining the optimal safety stock levels to prevent stockouts without excessive inventory.Case Studies and Examples: Business Inventory Systems

Businesses of various sizes and industries have leveraged inventory systems to enhance their operations and achieve remarkable outcomes. These case studies showcase real-world examples of successful inventory system implementations, highlighting the challenges faced and solutions adopted.

Retail Industry: Zara’s Agile Inventory Management

- Challenge: Rapidly changing fashion trends and high demand for new products.

- Solution: Implemented a just-in-time inventory system with frequent replenishments and data-driven forecasting.

- Outcome: Reduced inventory holding costs, increased product availability, and enhanced customer satisfaction.

Manufacturing Industry: Toyota’s Kanban System, Business inventory systems

- Challenge: Minimizing waste and improving production efficiency.

- Solution: Introduced a visual inventory system (kanban) to signal production needs based on actual demand.

- Outcome: Reduced inventory levels, improved lead times, and enhanced production flexibility.

Healthcare Industry: Hospital Inventory Optimization

- Challenge: Ensuring timely availability of critical medical supplies.

- Solution: Implemented an automated inventory management system with real-time tracking and predictive analytics.

- Outcome: Reduced stockouts, optimized inventory levels, and improved patient care.

Outcome Summary

By implementing a robust inventory system, businesses can gain a competitive edge by optimizing their inventory levels, reducing costs, and improving customer satisfaction. As technology continues to evolve, businesses should embrace emerging trends in inventory management to stay ahead of the curve and drive success.

Expert Answers

What are the benefits of using a business inventory system?

Business inventory systems offer numerous benefits, including improved inventory accuracy, reduced costs, increased efficiency, enhanced customer service, and better decision-making.

What are the different types of inventory systems?

There are various types of inventory systems, including perpetual inventory systems, periodic inventory systems, and hybrid inventory systems. Each type has its own advantages and disadvantages, and the best choice for a business will depend on its specific needs.

How can I optimize my inventory levels?

There are several strategies for optimizing inventory levels, including using inventory management techniques such as FIFO (first-in, first-out) and LIFO (last-in, first-out), implementing safety stock levels, and utilizing forecasting to predict demand.