Keeping inventory small business is crucial for financial success. This guide provides a comprehensive overview of inventory management techniques, helping small businesses optimize stock levels, reduce costs, and enhance profitability.

Effective inventory management ensures that businesses have the right amount of stock at the right time, avoiding overstocking and understocking. By implementing the strategies Artikeld in this guide, small businesses can streamline their operations, improve customer satisfaction, and maximize their bottom line.

Understanding the Importance of Inventory Management

Maintaining a lean inventory is crucial for small businesses to optimize their financial performance. Excessive inventory levels can tie up valuable capital, lead to storage and handling costs, and increase the risk of obsolescence and spoilage. Conversely, keeping inventory levels low offers numerous advantages, including improved cash flow, reduced expenses, and increased efficiency.

Benefits of Keeping Inventory Levels Low

- Improved Cash Flow: Lower inventory levels mean less money is tied up in unsold products, freeing up cash for other essential business operations.

- Reduced Storage and Handling Costs: With less inventory on hand, businesses can reduce the size of their storage facilities and the associated costs of rent, utilities, and labor.

- Decreased Risk of Obsolescence and Spoilage: By minimizing inventory levels, businesses reduce the likelihood of holding onto outdated or perishable products that may lose value or become unsaleable.

- Increased Efficiency: Lean inventory management allows businesses to streamline their operations, reduce waste, and improve productivity by focusing on essential products and eliminating unnecessary stock.

Avoiding Overstocking and Understocking

Striking the right balance between overstocking and understocking is essential for effective inventory management. Overstocking can lead to financial losses due to excessive storage costs, obsolescence, and spoilage, while understocking can result in lost sales and customer dissatisfaction. To avoid these pitfalls, businesses should:

- Conduct Regular Inventory Audits: Regularly tracking inventory levels helps identify slow-moving or obsolete products and adjust stocking levels accordingly.

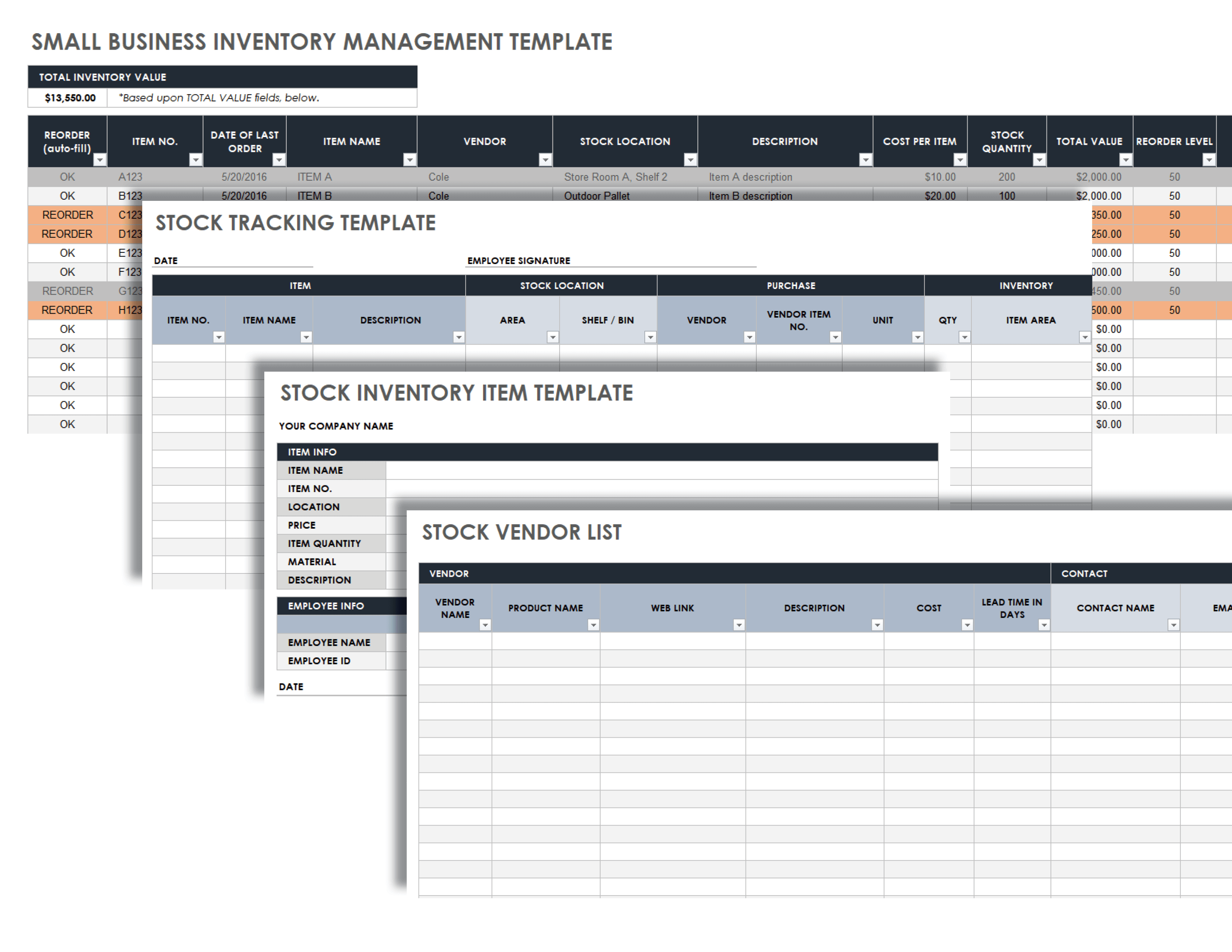

- Use Inventory Management Software: Automated systems can streamline inventory tracking, provide real-time updates, and generate alerts when stock levels are low or excessive.

- Implement Just-in-Time (JIT) Inventory: JIT systems minimize inventory levels by ordering products only when they are needed, reducing storage costs and the risk of overstocking.

- Monitor Sales Trends and Customer Demand: By analyzing sales data and customer feedback, businesses can better anticipate demand and adjust inventory levels to meet customer needs.

Effective Inventory Tracking Methods: Keeping Inventory Small Business

Inventory tracking is crucial for small businesses to optimize stock levels, prevent overstocking or understocking, and ensure efficient operations. Effective inventory tracking methods empower businesses to make informed decisions, reduce waste, and enhance profitability.

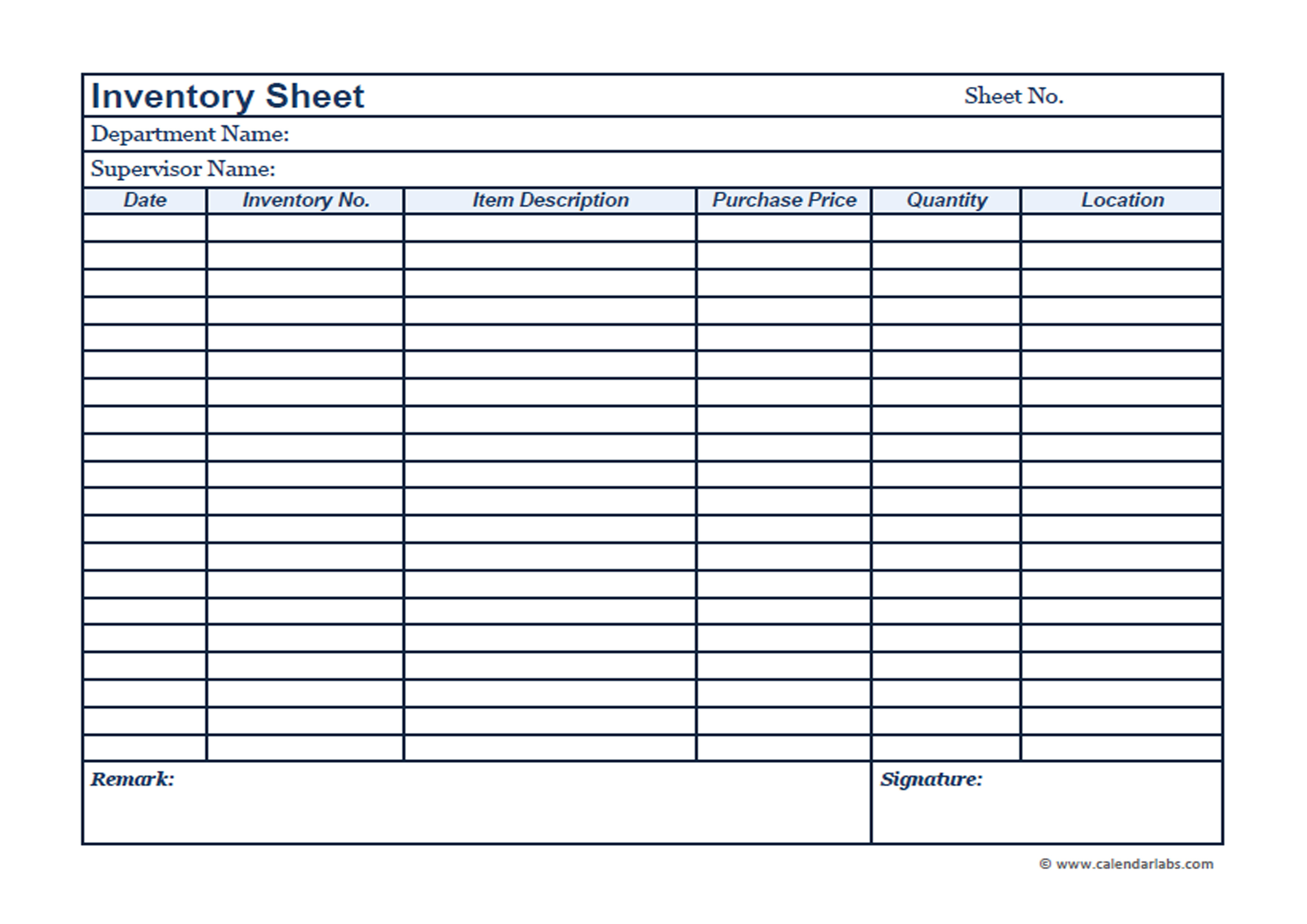

Manual vs. Automated Inventory Tracking Systems

Businesses can choose between manual and automated inventory tracking systems, each with its advantages and disadvantages:

Manual Inventory Tracking

- Advantages: Low cost, easy to implement, suitable for small businesses with limited inventory.

- Disadvantages: Prone to human error, time-consuming, limited data insights.

Automated Inventory Tracking

- Advantages: Accurate, efficient, provides real-time data, integrates with other business systems.

- Disadvantages: Higher cost, requires technical expertise, may need customization.

Choosing the Best Inventory Tracking Method, Keeping inventory small business

The choice between manual and automated inventory tracking depends on several factors:

- Inventory size and complexity: Automated systems are more suitable for large and complex inventories.

- Budget: Manual tracking is less expensive, while automated systems require investment.

- Staff expertise: Automated systems may require technical knowledge, while manual tracking is less demanding.

- Integration with other systems: Automated systems often integrate with accounting, sales, and other business software.

Small businesses with limited inventory and budget may find manual tracking sufficient. However, as inventory grows or business operations become more complex, automated inventory tracking systems offer significant advantages in terms of accuracy, efficiency, and data insights.

Optimizing Inventory Levels

Effective inventory management is crucial for small businesses to minimize costs, maximize profits, and enhance customer satisfaction. Optimizing inventory levels is a key aspect of this process, ensuring the right amount of stock is available at the right time.

Just-in-Time (JIT) Inventory Management

Just-in-time (JIT) inventory management is a strategy that aims to minimize inventory levels by receiving goods only when they are needed for production or sale. This approach reduces storage costs, minimizes waste, and improves cash flow.

To implement JIT in a small business:

- Establish strong relationships with suppliers to ensure reliable and timely deliveries.

- Implement a system for accurate demand forecasting to predict customer needs.

- Streamline production processes to reduce lead times and increase efficiency.

- Use inventory management software to track stock levels and trigger orders when necessary.

Forecasting Demand and Adjusting Inventory Levels

Forecasting demand is crucial for optimizing inventory levels. Small businesses can use historical sales data, market trends, and customer feedback to predict future demand. This information can be used to adjust inventory levels accordingly:

- During peak demand periods, increase inventory levels to meet customer needs and avoid stockouts.

- During slow periods, reduce inventory levels to minimize storage costs and prevent spoilage.

- Use safety stock to buffer against unexpected fluctuations in demand or supply.

Reducing Inventory Costs

Inventory costs extend beyond the purchase price of goods. Understanding and managing these hidden costs can significantly impact your bottom line.

Negotiating favorable terms with suppliers can help reduce costs. Building strong relationships, understanding market trends, and leveraging economies of scale can yield better deals.

Minimizing Inventory Shrinkage

Inventory shrinkage refers to the loss of inventory due to theft, damage, or misplacement. Implementing robust security measures, such as surveillance cameras, access control systems, and regular inventory audits, can minimize shrinkage.

Integrating Inventory Management with Other Business Functions

Inventory management plays a pivotal role in the overall success of a business, as it directly impacts various other functions and departments. Understanding these interconnections is crucial for optimizing inventory levels and ensuring efficient operations.

Effective inventory management ensures that the right products are available at the right time, fulfilling customer demand while minimizing waste and unnecessary costs. It directly affects sales by ensuring product availability and timely order fulfillment. By integrating inventory management with sales, businesses can track customer orders, adjust inventory levels accordingly, and prevent stockouts that can lead to lost sales.

Inventory management also influences purchasing decisions. By monitoring inventory levels and demand patterns, businesses can optimize purchase orders, ensuring that they have sufficient stock without overstocking. This collaboration between inventory management and purchasing helps prevent excess inventory, reduce storage costs, and improve cash flow.

Furthermore, inventory management is closely linked to production planning. Accurate inventory data allows businesses to plan production schedules effectively, ensuring that they have the necessary raw materials and components to meet demand. This integration helps avoid production delays, optimize resource allocation, and minimize lead times.

Flowchart: Integrating Inventory Management with the Supply Chain

The following flowchart illustrates the integration of inventory management with the supply chain:

[Flowchart diagram showing the integration of inventory management with suppliers, production, sales, and customers]

Importance of Collaboration

Collaboration between different departments is essential for optimizing inventory levels. When sales, purchasing, and production teams work together, they can share information, coordinate activities, and make informed decisions that benefit the overall business.

Effective communication and data sharing among these departments allow businesses to align inventory levels with demand, avoid overstocking or stockouts, and respond quickly to changes in the market. Collaboration fosters a proactive approach to inventory management, enabling businesses to anticipate demand and make adjustments accordingly, ensuring smooth operations and customer satisfaction.

Ultimate Conclusion

In conclusion, keeping inventory small business is essential for optimizing operations, reducing costs, and ensuring financial stability. By implementing effective inventory management techniques, small businesses can gain a competitive edge, increase profitability, and lay the foundation for long-term growth.

Query Resolution

What are the benefits of keeping inventory levels low for small businesses?

Lower carrying costs, reduced risk of obsolescence, improved cash flow, and increased agility.

How can I avoid overstocking and understocking?

Implement just-in-time inventory management, forecast demand accurately, and monitor inventory levels regularly.

What are some techniques for reducing inventory costs?

Negotiate better deals with suppliers, implement inventory control measures, and optimize warehouse space utilization.